Other OHP Products

From spacecraft to semiconductors, precision thermal control is critical. In addition to the most common OHP products (chassis, frames, radiators), we also provide the following products for land, sea, air applications. Let us solve your heat transfer problems today.

Built for Performance. Designed for Flexibility.

OHP Battery Packages

Passive, lightweight cooling for high-power density battery systems.

When power, weight, and reliability matter, OHP-embedded carriers, frames, and spines offer a compact way to manage heat across densely packed cells. These modules are built high discharge/charge rates in demanding applications onboard spacecraft, UAVs, and tactical ground systems.

The form factor can be made into any shape or size (e.g. prismatic or cylindrical), and with thicknesses as low as 1mm.

Efficient, passive heat transport. Can move 10s - 100s of Watts from 4-40x the heat transfer rate of solid aluminum.

Scalable and modular layout options, each OHP structure can house 10s of cells, and can be arrayed to manage of 100s to 1000s of cells.

Best fit for systems where active thermal loops are impractical or undesired. A hybrid solution combining OHPs with pumped fluid loop heat exchangers can be utilized for maximum thermal performance.

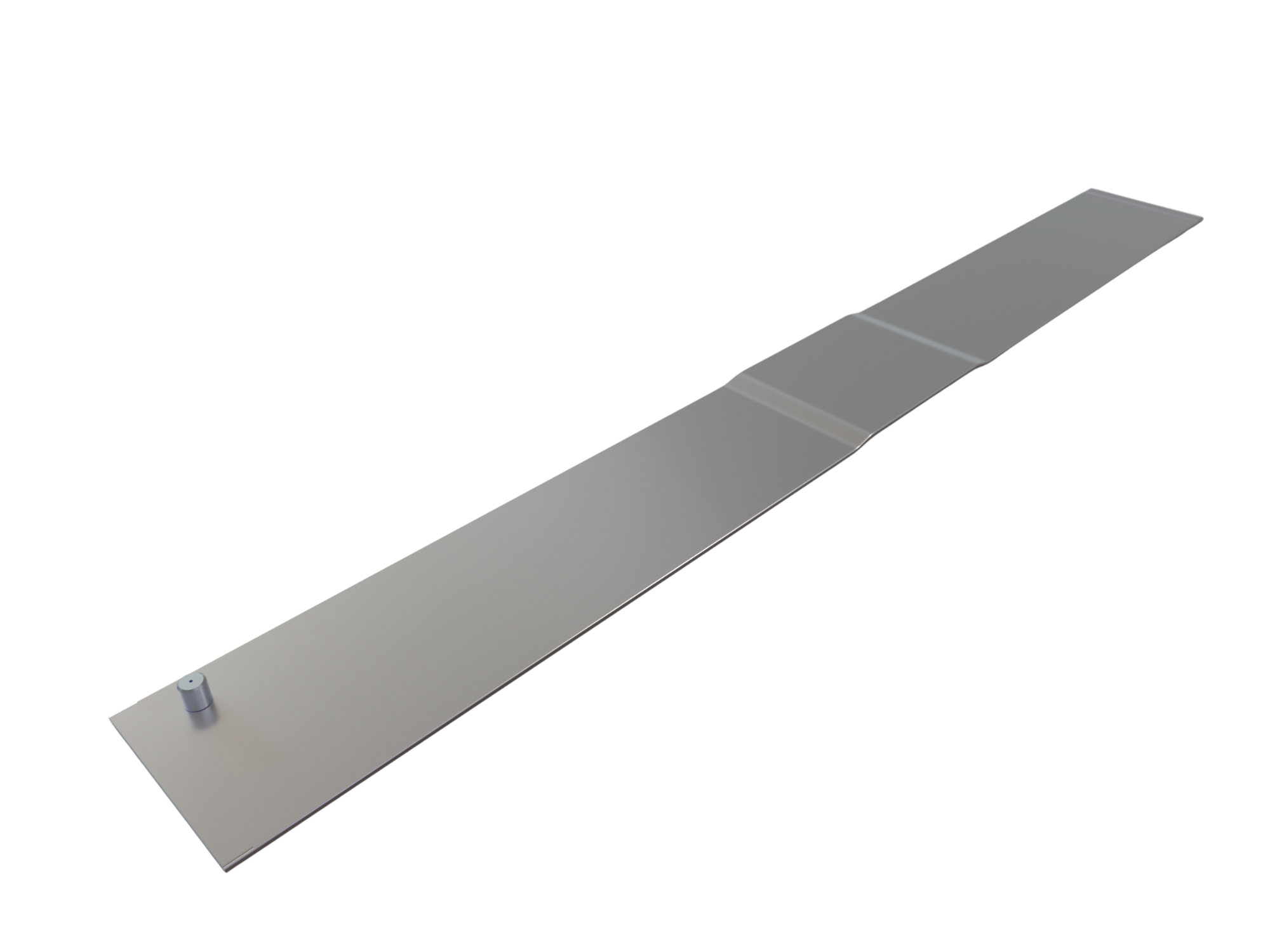

OHP Thermal Straps

High performance thermal busses for transporting heat loads.

OHPs thermal straps effectively transport waste heat from microchips or other power sources relatively long distances (e.g., <0.1 to >1.1 meter) through relatively thin cross-sections (e.g., >1mm to <5mm thick and 25-250mm wide) at ultra-high effective thermal conductivities (e.g., 1000 W/mK to 100,000 W/mK). Other features and benefits of OHP thermal straps:

Designable as rigid (high yield strength) structures or as flexible (low-yield strength) straps that trin 2-D or 3-D form factors.

Configurable for managing heat loads from one or multiple heat sources to one or more heat sinks.

Precision built out-of-plane fluid paths that are either bent (e.g., internal radius of 3x OHP thickness) or monolithically built with sharp 90-degree internal out-of-plane turns to conform to a platform’s space claim.

Contact our engineering team if you want to learn more about deployable and flexible OHP straps.

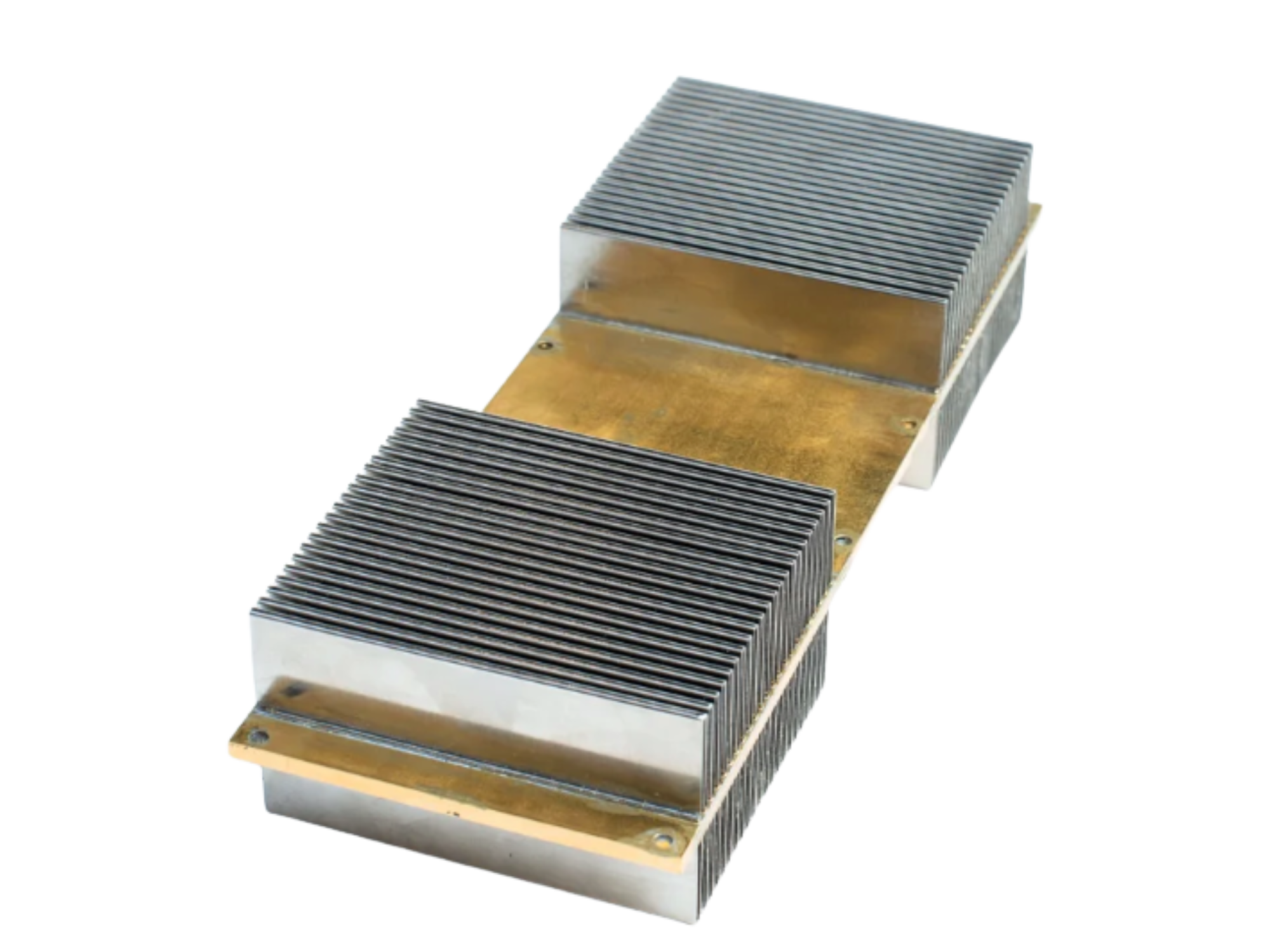

OHP Air Cooled Heat Sinks

Enabling simple, low-cost and air-cooled payloads with OHP-embedded heat sinks.

Conventional air-cooled heat sinks often face thermal limits due to inadequate heat spreading from critical devices to their larger natural- or forced air boundaries. By embedding the OHP into the base material, high flux devices’ waste heat can be rapidly acquired, spread and then rejected across a more isothermal heat rejection area to increase fin efficiency and remove those thermal bottlenecks – and do so without having to redesign your layout (or skyline) or cooling methods.

3-5x higher thermal conductance (W/K) than solid metal base heat sink due to increased fin efficiency (i.e., reduced hot spots)

Fins can be bonded, fastened, or monolithically bonded to the OHP-embedded base.

20-30% reduced mass vis-à-vis solid metal base

Operable across a range of operating conditions (e.g., sea-level to >35,000 feet, from -1g or greater adverse gravity fields, from less than -20C to +85C, etc.)

Air-cooled OHPs have been demonstrated for a range of applications from electronics chassis to optical devices and even sealed, externally-cooled server trays (1U or greater).

OHP Packages and Heat Spreaders

Thin, planar device-level OHP heat spreaders (or packages) capable of transforming high fluxes from critical devices across larger rejection boundaries with minimal temperature rise.

OHP heat spreaders are effective tools for opto-electronics packages where relatively high heat flux heat devices need to have their waste heat acquired, spread and rejected across a larger rejection boundary, especially when the package profile needs to be extremely compact (e.g. thicknesses from 1-4mm)

Producible in a range of materials, including low-CTE (coefficient of thermal expansion) refractory metals or ceramics to enable either metal or polymer thermal interfaces (i.e., device attachment methods)

OHP microchannels can support compressive loading (similar to the base material’s stiffness) and designed with 3D internal geometries to route heat from devices to their rejection areas, even when such rejection boundaries are on different planes.

Device level heat fluxes of 30, 100 and greater than 300 W/cm2 easily managed by the OHP, whereas conventional wick-based heat pipes or vapor chambers struggle to combine high flux and thin profiles

Available in centimeter-scale packages to meter-scale spreaders, depending end-user application and ultimate heat rejection boundary conditions.

OHP-based spreaders, chip carriers and device-level packages are optimal for concentrated heat load dissipation from SSPAs, laser diodes, high-powered processors (CPUs or GPUs) and multi-chip modules (or systems on chips) in terrestrial and space-based platforms.

OHP Heat Exchangers

High performance interfaces between devices, hot fluid loops, coolant fluid loops, airstreams, and ambient rejection environments.

OHPs can optimize the handoff between thermal systems by being built directly into existing heat exchanger geometries. Systems can be fully customized to interface between pumped fluid loops, airstreams, and heat generating devices.

OHPs can be integrated to increase effective heat transfer rates from heat sources to the rejection boundary.

Built to specification or fully customizable to the application.

ThermAvant's heat exchangers can support a number of working fluids such as PAO, ethylene glycol, etc.

Heat exchanger thermal systems can be used for large OHP radiator arrays for lunar and space applications with pumped fluid loop interconnects. They can also be employed for airborne fuel to airstream heat dissipation applications.

You Bring the Mission.

We Bring the Solution.

Product Development. Manufacturing. Testing.

From concept to final delivery, ThermAvant partners with your team to design and manufacture OHP-embedded solutions that meet the exact needs of your system.

We support every step:

Collaborative design and modeling based on your layout and power profile

In-house prototyping (in-house brazing and CNC machining capabilities)

On-site lab facilities with high fidelity thermal verification testing

Precision manufacturing for high-volume delivery with robust demand schedules