Products

ThermAvant Tech is the world’s leading Oscillating Heat Pipe (OHP) provider to aerospace, defense, and high-technology firms who rely on our team to develop and deliver best-in-class thermal solutions for their higher power density opto-electronics and energy systems.

Other Products

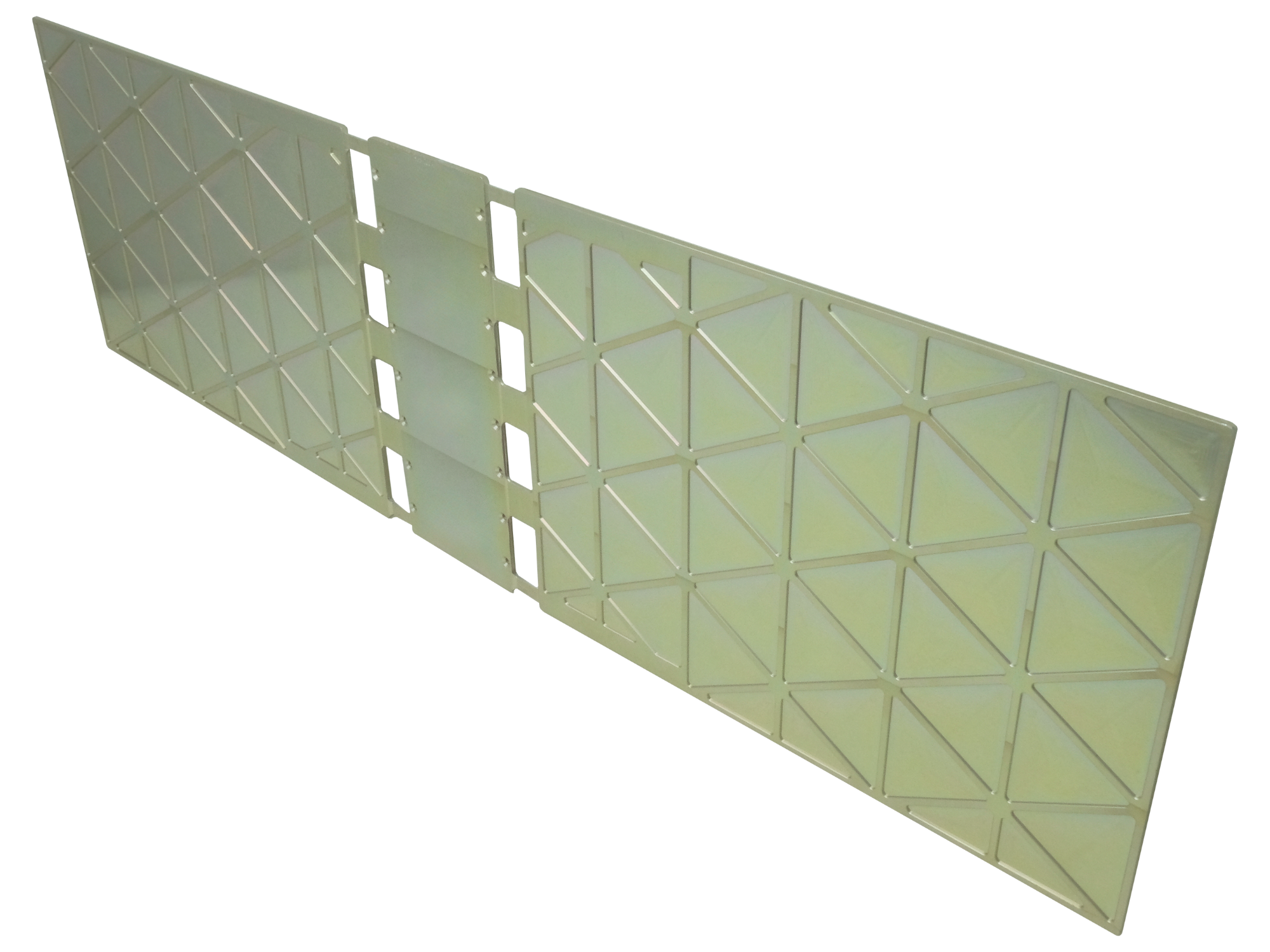

Explore Our OHP Packages and Heat Spreaders

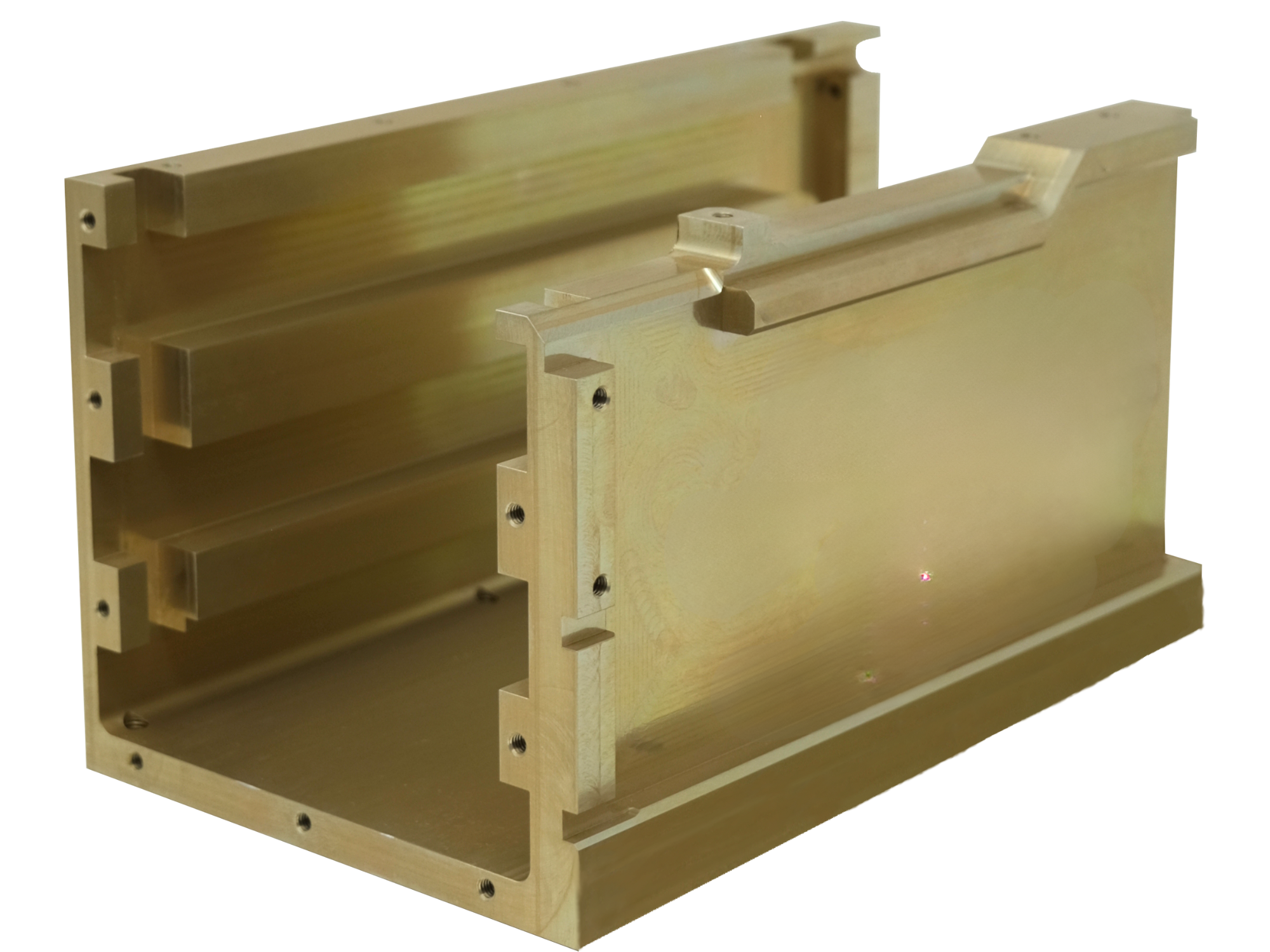

Explore Our Cold Plates

Explore Our OHP Battery Packages