SINGLE- AND TWO-PHASE

Cold Plates

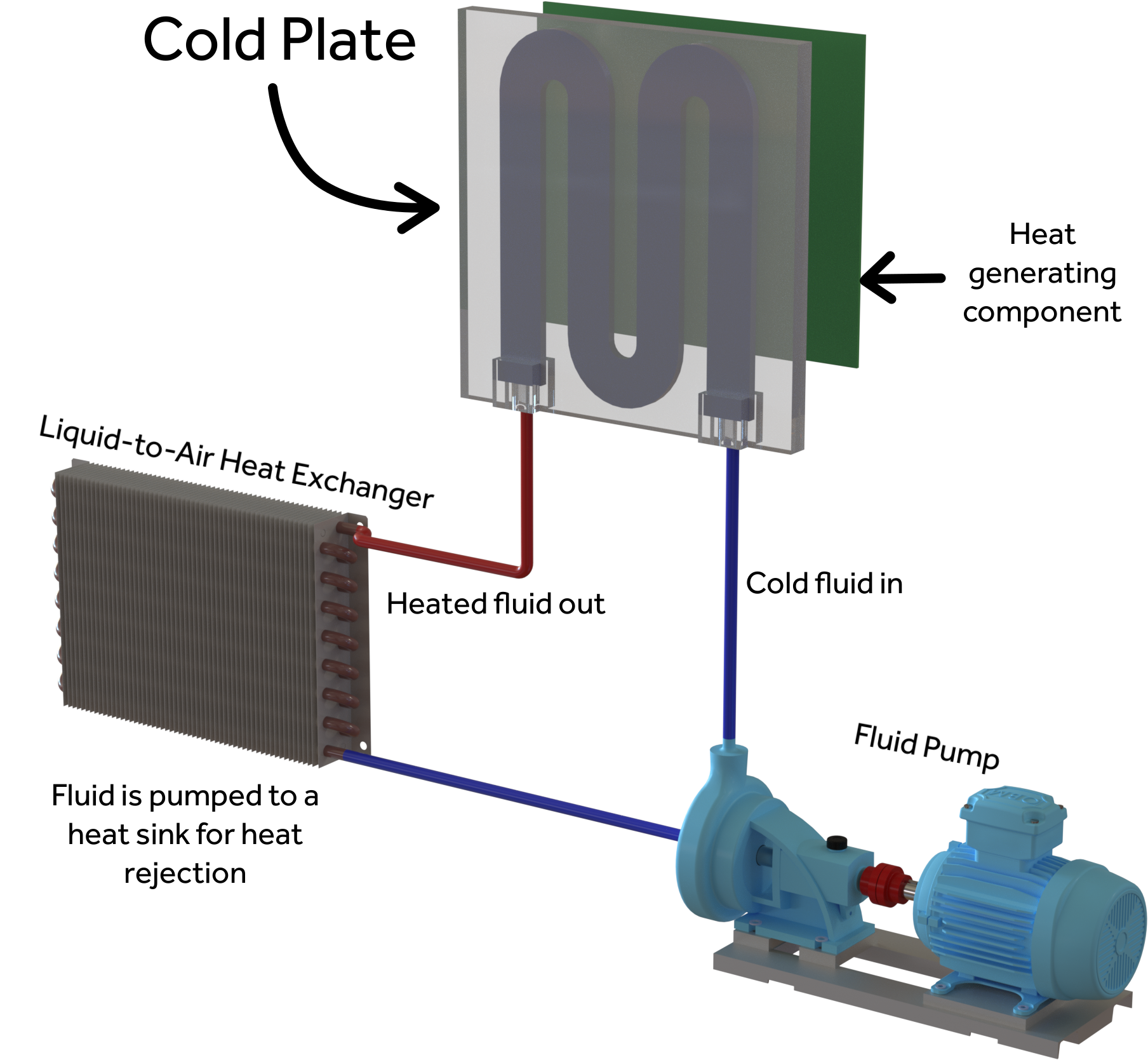

A cold plate is a type of pumped fluid heat exchanger designed to remove heat from high-power electronics by providing a direct interface between the heat-generating components and a circulating coolant.

ThermAvant Technologies’ cold plates improve heat transfer while maintaining structural integrity and are designed for a wide range of applications where the heat transfer coefficient (h, W/m²-K) must be optimized within system constraints.

For compact, high-performance needs, we use micromachined channels, brazed and milled to extract maximum heat for a given fluid, flow rate, and pressure drop. For simpler use cases, we use simpler, lower-cost fabrication methods.

Aerospace • Defense • Industrial Systems

Cold Plate Product Gallery

The products below show customized solutions with proprietary details removed.

Inlaid Tube Cold PlateSelectively coated

With inlaid large diameter tubing bonded to super structure

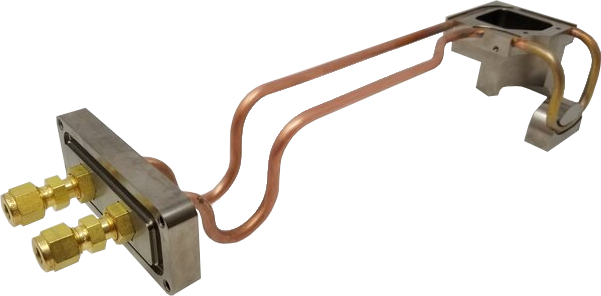

Simple Bent Tube Copper-Aluminum Cold Plate AssemblyPrecision bent Cu tubing bonded to multiple Al structures

Compression fittings

Designed as a retrofit for existing system’s overheating internal components

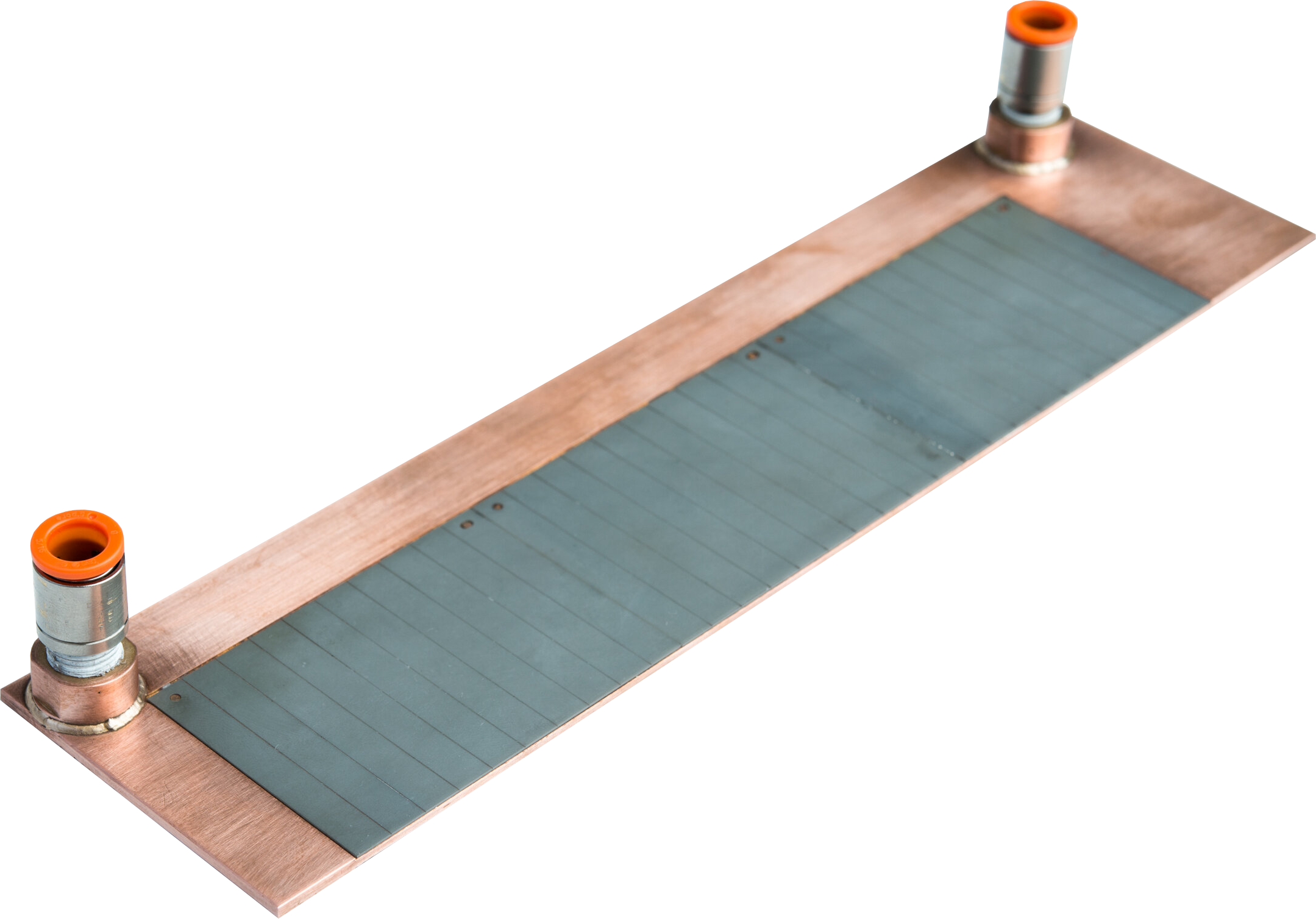

Aluminum Nitride on Copper Cold PlateLow-CTE AlN substrate bonded to Cu cold plate

mm scale internal microchannels

Push-to-connect cold plate fittings

Brazed Aluminum Cold PlateMounting structure for high-power electronics

Chem film coating

Ultra-high heat transfer rates achieved with complex internal flow path features

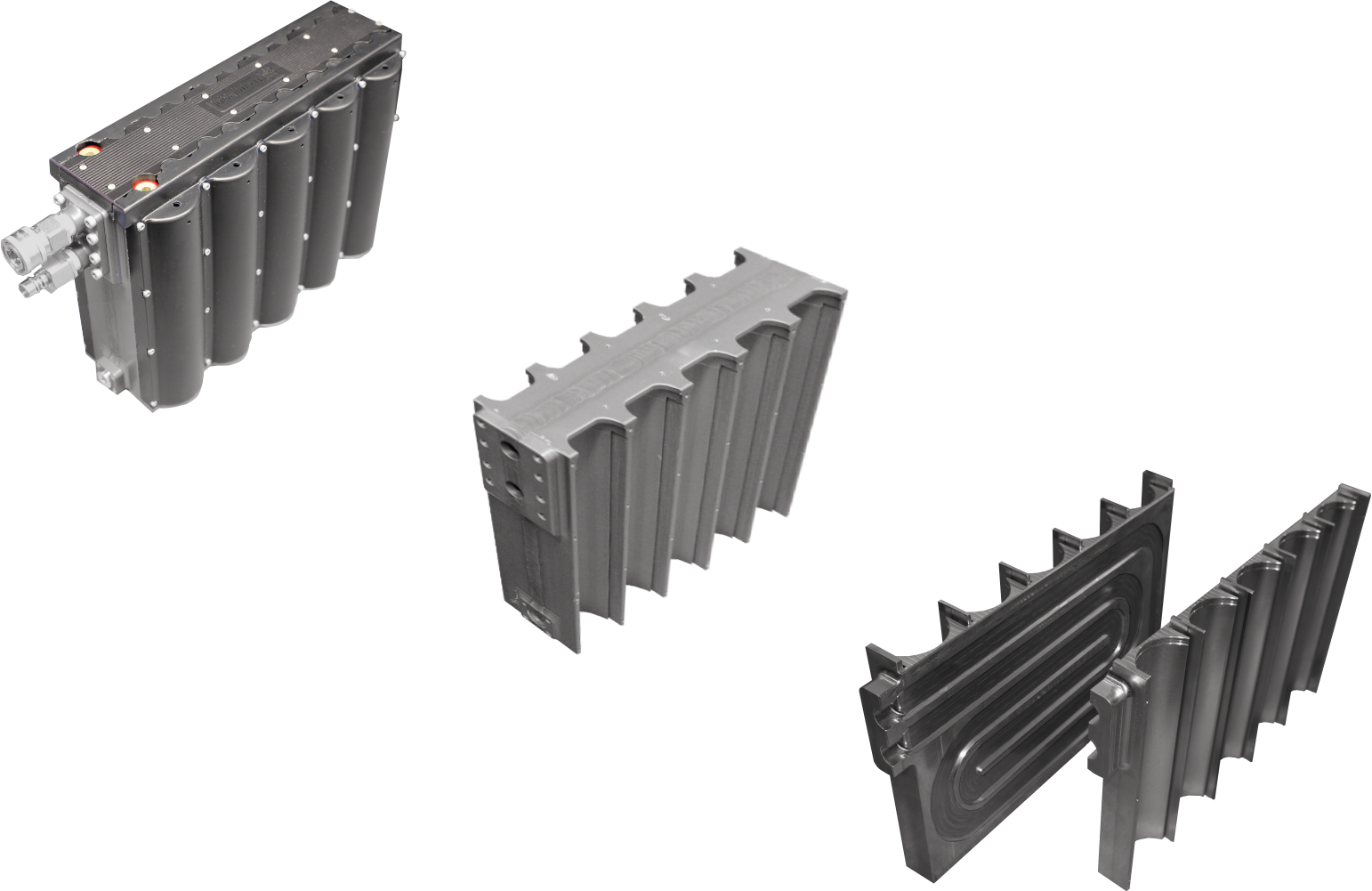

Simple Welded Cold Plate

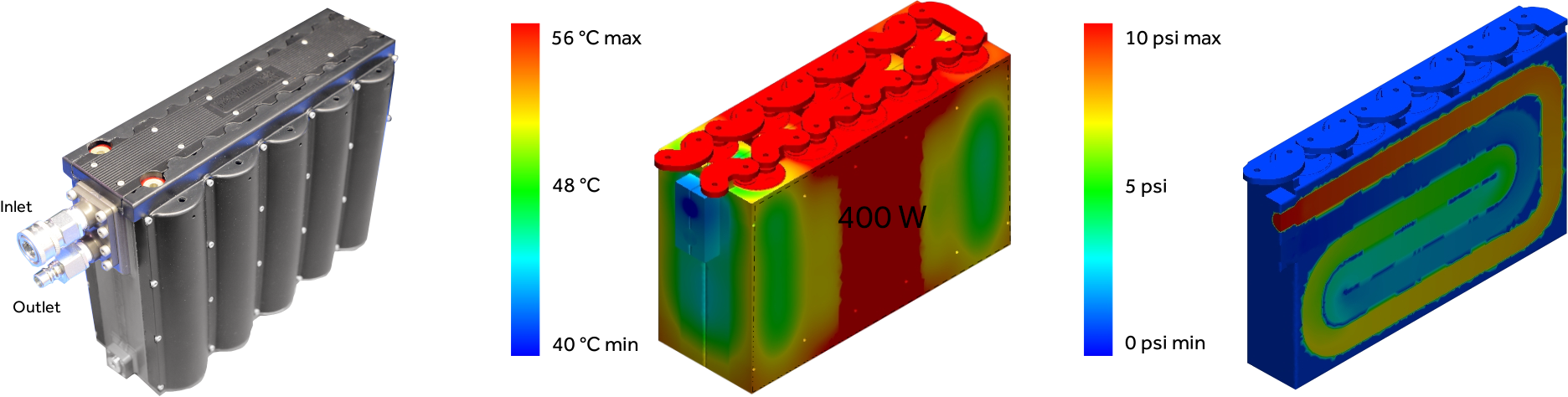

ThermAvant Techonlogies developed and delivered a battery package for high-power-density Li-ion cells. Its cold plate core was manufactured from two individual Aluminum plates with CNC machined flow paths. The plates were then welded into a single structure whose exterior was machined again to precise specifications, then dielectrically coated, and outfitted with fittings and interfaces for the cells, bus work and protective covers.

The solution offered a cost-effective, safe battery package for the end-customer using a relatively straightforward, multi-pass flow path to remove the cells’ waste heat. And, while there was a relatively large pressure drop when compared to a more complex brazed cold plate solution, the customer had ample pumping power available and prioritized lead time and cost over efficiency

Example of a Simple Welded Cold Plate

Battery package

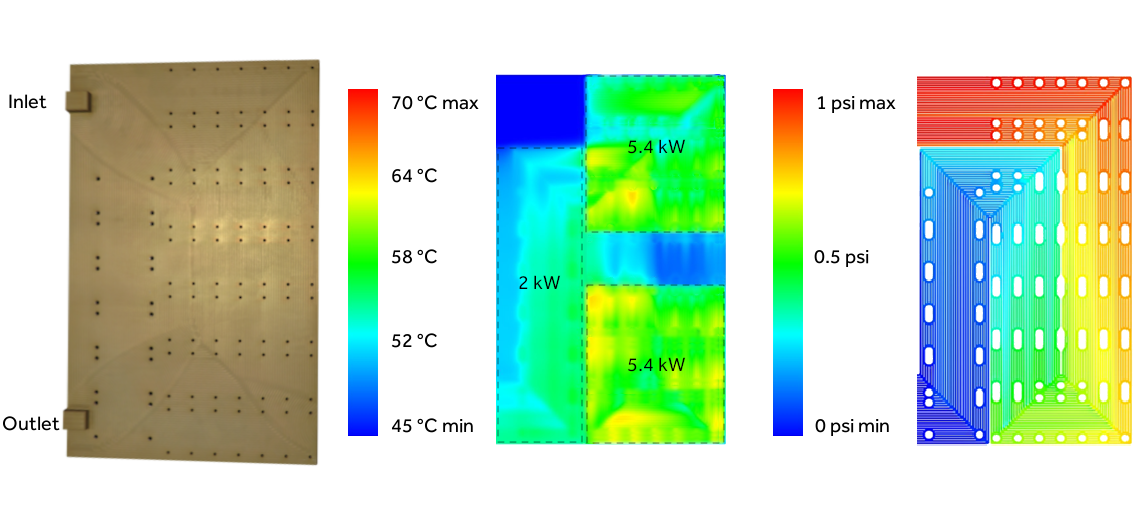

Complex Brazed Cold Plate

ThermAvant Technologies develops and delivers a power electronics cold plates for mission-critical applications where optimized internal flow paths are formed and bonded using CNC machining and vacuum brazing. Internally, there are multiple layers, fin structures, and turbulators to maximize heat transfer performance and minimize pressure drop. Brazed cold plates such as this one are preferable when there is limited size, weight and power available and performance and reliability are paramount.

While relatively more expensive and longer lead times than a welded or inlaid tube cold plates, brazed cold plates remove orders of magnitude more heat and are able to withstand extreme pressures, forces and other environmental conditions found in many mission-critical end-uses.

Example of a Complex Brazed Cold Plate

Aerospace and defense vehicular power electronics assembly

Cold Plate Tech Specs

Design flexibility and SWaP-C optimization without compromise.

-

Al and Al composites (from 0 to T6 temper) (most common)

Cu and Cu composites, including Copper-Molybdenum

Stainless steel

-

Deionized water (with corrosion inhibitors and internal channel chem film)

EGW

PGW

PAO

-

Designed to meet customer thermal scenario needs

Heat fluxes up to 50 W/cm2 (can handle more concentrated loads when integrated with an oscillating heat pipe.

Temperatures will be fluid dependent from ranging from cryogenics to traditional electronics cooling temperatures to intermediate/high temperature regimes.

-

From less than 1 mm in thickness to up to 2 m in length

Customizable widths from less than 2 cm to greater than 1 m

Flat or 3D plate with bosses, through or blind holes, etc.

Platings and dielectric coatings

Chemical conversion coating and anodization

Cold Plate FAQs

-

Microchannel PFL cold plates are typically made in aluminum 6061. They incorporate a high density internal channel pattern, designed for the thermal management of high flux heat inputs. Microchannel cold plates have increased surface area in contact with the pumped coolant, resulting in an enhanced effective heat removal rate over traditional cold plates.

-

Lead times can be as short as 4 weeks for recurring hardware. Custom designs and new builds typically range from 4 to 6 months for first unit delivery, depending on complexity.

-

Yes. Microchannel PFL cold plates follow the same manufacturing steps as oscillating heat pipe and can be readily combined with the proper design effort. Such thermal solutions can provide a low pressure drop and low complexity pumped fluid option transporting large amounts of heat long distances. At the same time the OHP spreads the heat from concentrated heat loads over larger interfaces with the pumped fluid loop. This effectively emulates the heat transfer coefficients achievable with a pumped two phase solution in a much less complex system. Both the PFL and OHP are incorporated in the same monolithic piece of raw material without additional thermal interfaces.

-

ThermAvant has several PFL cold plates that can be produced and delivered without additional design work. Most designs will be custom designed to support complex heat maps and demanding performance requirements.

-

ThermAvant's cold plates are fabricated through microchannel machining and brazing to form high channel density inner flow paths. The microchannel maximize the surface interface with the coolant allowing for effective heat removal rates higher than that of inlaid tube cold plates. Inlaid tube designs require relatively large diameter tubes bent and pressed into thick plate of a raw material (e.g., aluminum). The tubes can be soldered or epoxied into place adding an additional thermal interface increasing the resistance stack. The large diameter tubes have limited bend radii minimums which effects the ability to route tubes in complex patterns to all areas of a cold plate's surface.

-

Yes. ThermAvant's microchannel cold plates are brazed then machined out of a heretically sealed aluminum stack yielding cold plate architecture, skyline features, and inlet/outlet ports that are monolithically integrated with the main surface of the cold plate.

-

Yes. ThermAvant's cold plates can be manufactured with through-holes and threaded or tapped features, allowing for structural mounting to higher-level assemblies and seamless attachment to critical components.

-

Yes. Microchannel cold plates can be designed and fabricated with complex external geometries and intricate internal channel routing—without compromising the structural integrity of the component.

-

ThermAvant's cold plate microchannels form structural "I-beam" features within the part’s cross-section. This allows an cold plate to retain most of the strength and stiffness of the base material. ThermAvant can provide effective structural properties to support efficient modeling during preliminary design stages at the system level.

-

Microchannel cold plates typically have better heat transfer performance, high effective heat removal rates, and structural but lower mass. Inlaid tube cold plates will typically have a lower pressure drop due to the large diameter tube and are simple/less expensive to make.

-

No. Microchannels are machined into the raw material and can be incorporated in thin cross sections down to a few millimeters in thickness. Traditional inlaid tube cold plates require thickness for the tube and structural material to accommodate their press fit into the base which results in a much heavier part.

-

ThermAvant's cold plates are primarily aluminum 6061 and should be run with compatible fluids with corrosion inhibitors to ensure long life. EGW, PGW, and PAO are common coolants used in aluminum cold plates.

-

ThermAvant's has the lab facility and design capability to emulate most boundary and environmental conditions. Custom thermal test vehicles with replicative resistive heat loads can be design to emulate critical device output. ThermAvant can also perform leak checks, proof pressure, burst pressure, and flow through performance tests.

-

ThermAvant has manufactured cold plates as small as a few inches square in footprint to meter long pumped fluid loop integrated plates and OHP integrate/PFL radiators.

-

OHPs are manufactured in 3 major steps: 1) initial machining, 2) bonding, and 3) final machining. Items that will drive unit cost are heat map complexity, final part GD&T, part size, material, etc. Please engage the ThermAvant business development team for more information on hardware and design NRE pricing.

You Bring the Mission.

We Bring the Solution.

Product Development. Manufacturing. Testing.

From concept to final delivery, ThermAvant partners with your team to design and manufacture OHP-embedded solutions that meet the exact needs of your system.

We support every step:

Collaborative design and modeling based on your layout and power profile

In-house prototyping (in-house brazing and CNC machining capabilities)

On-site lab facilities with high fidelity thermal verification testing

Precision manufacturing for high-volume delivery with robust demand schedules