OSCILLATING HEAT PIPE

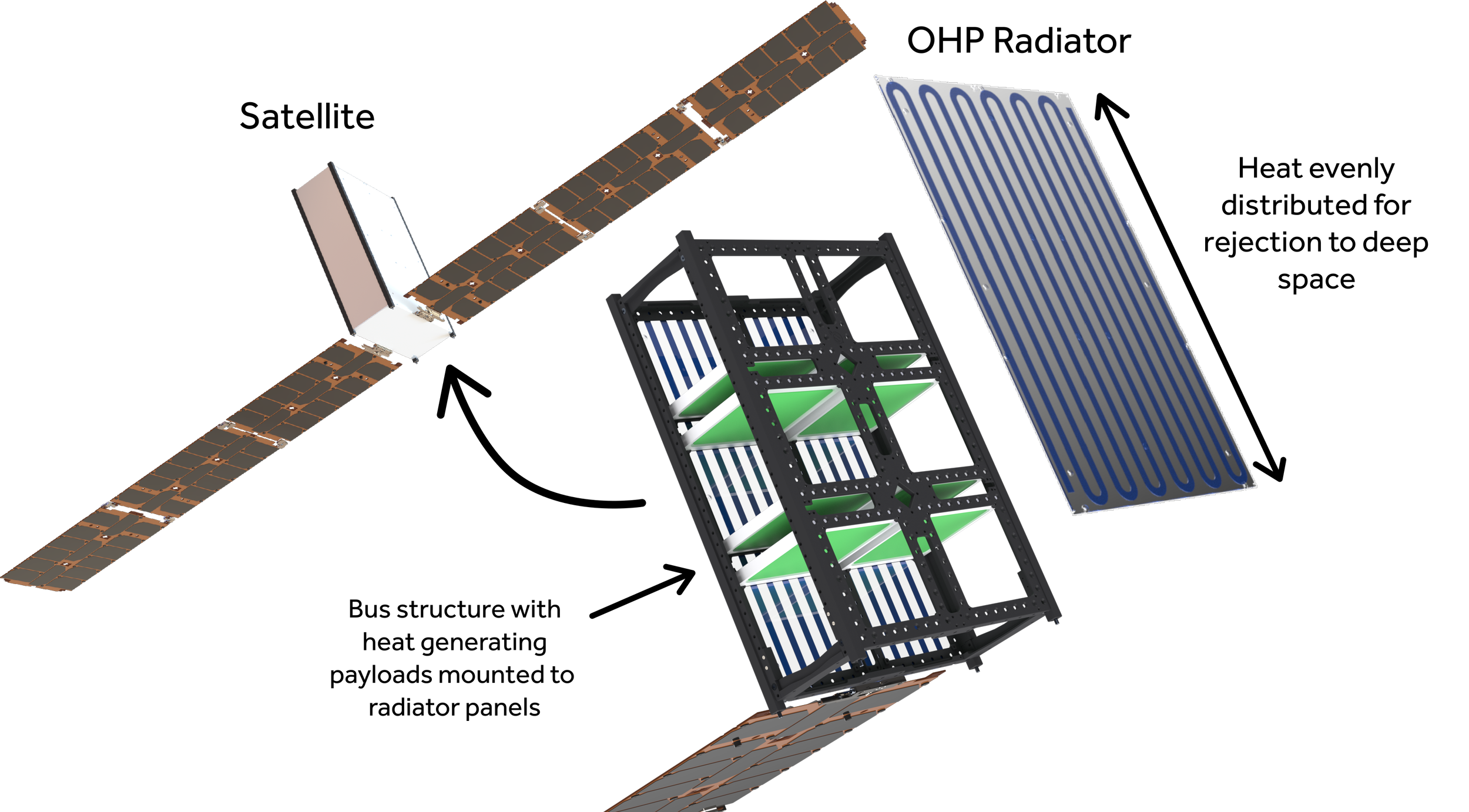

Radiators

Radiators are the rejection component of a spacecraft’s thermal control system where waste heat from onboard electronics, power-energy systems, RF devices, sensors, life support and other payloads is expelled.

ThermAvant Technologies’ OHP-embedded radiators are designed as simple 2-D or complex 3-D form factors. OHPs can be used as a purely thermal solution (e.g., thin, long-distance straps bonded to the spacecraft’s structural panels), or they can be designed into the structural panels as a multifunctional solution. ThermAvant Technologies has even developed deployable OHPs.

Commercial and defense satellite makers are increasingly transitioning to OHP-based radiators for their next-generation spacecraft to optimize tradeoffs of size, weight, power and cost – as well as reduced complexity of integration.

Commercial Space • Defense Spacecraft

OHP Radiator Product Gallery

The products below show customized solutions with proprietary details removed.

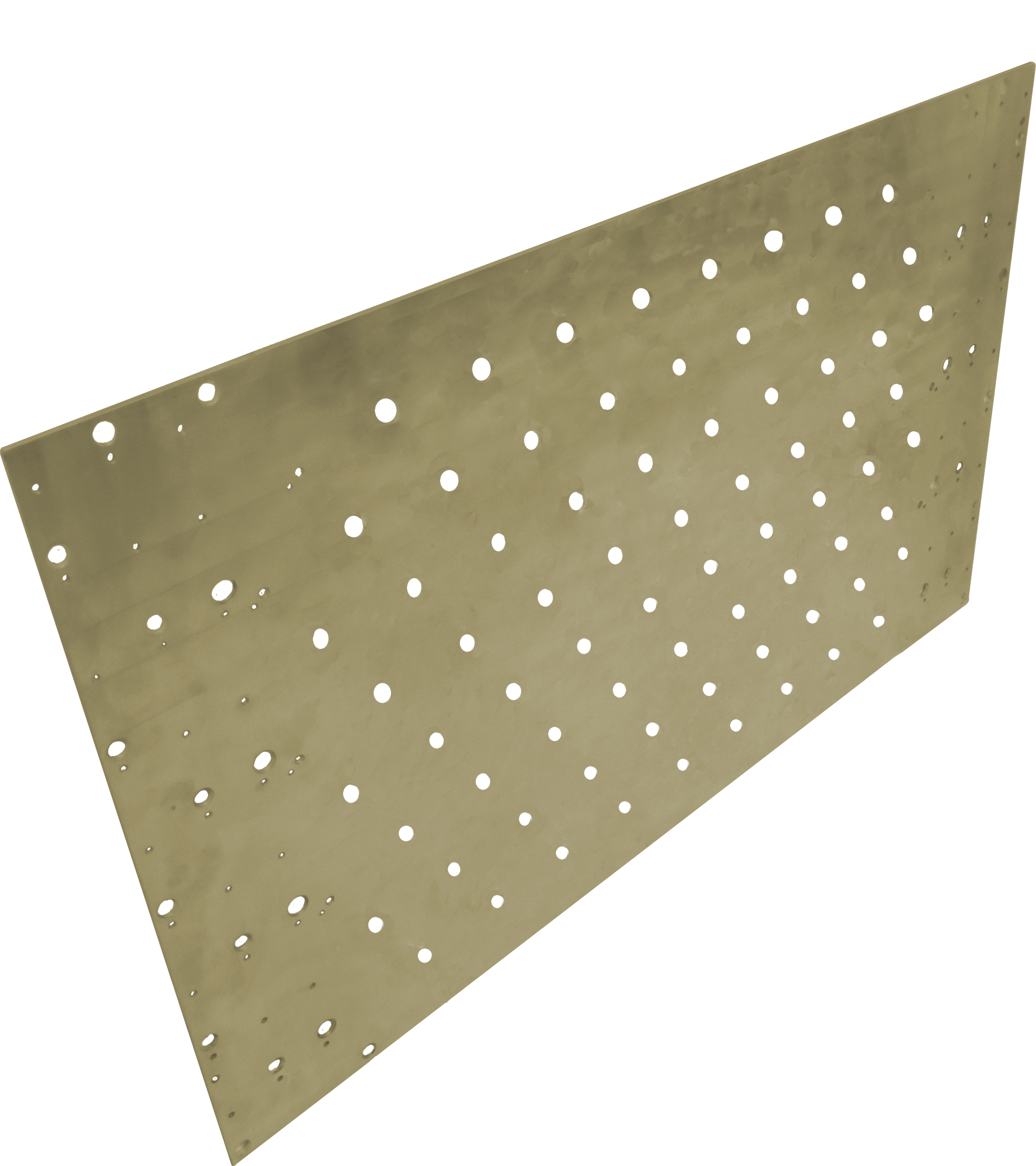

Smallsat RadiatorIso-grid for structural rigidity

Example 6U satellite configuration

Satellite structure becomes heat rejection surfaces

Structural Spacecraft Radiator BaseplateCustom finishes for space environment

Direct PCB mounting features

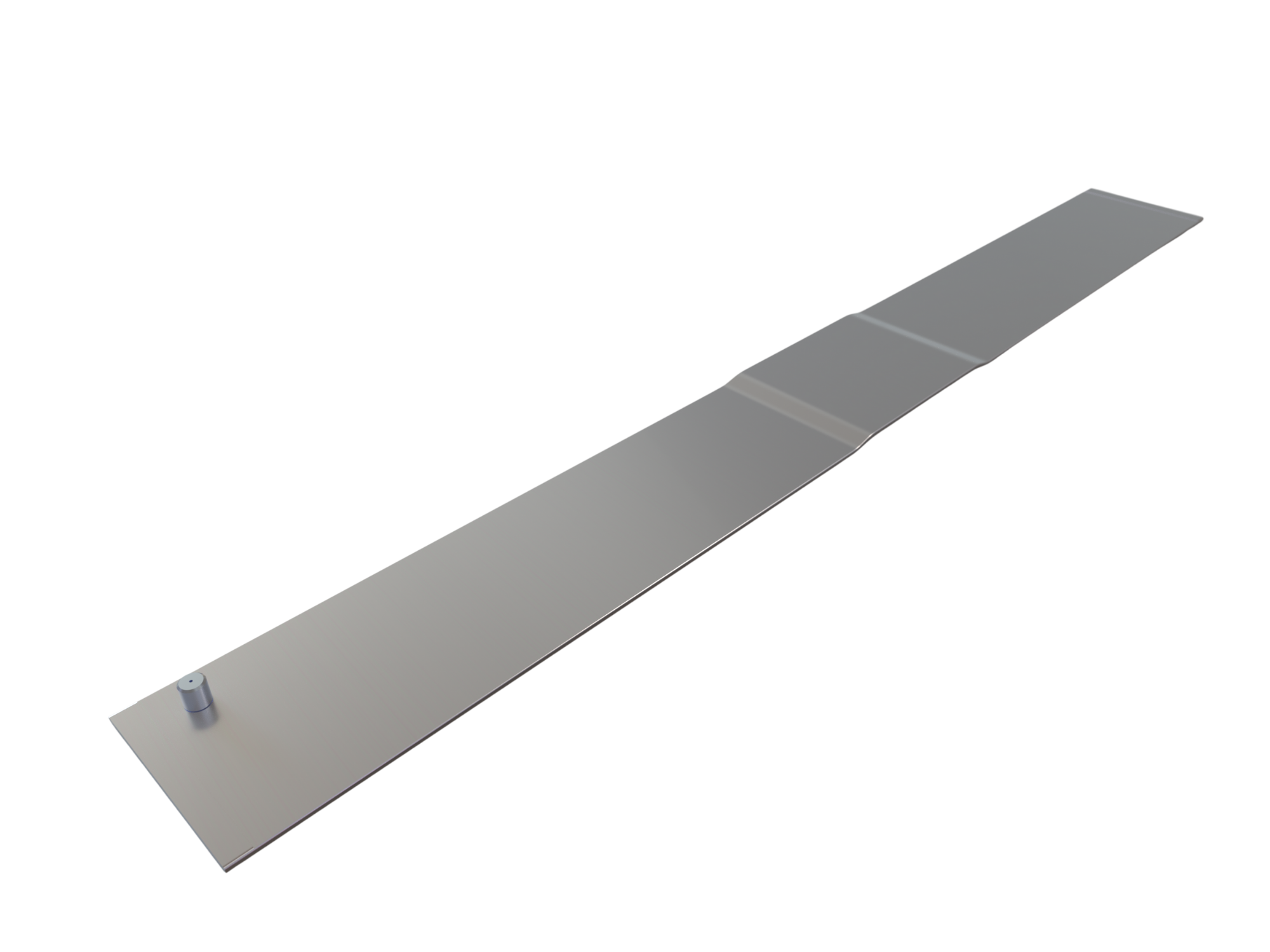

Meter Scale Spacecraft RadiatorHigh-tolerance mechanic features

Complex OHP channel routing for spreading heat from multiple devices of varying heat loads across a meter+ distances

2- and 3-D Radiator StrapTypically sized from 0.2m to 1.5m in length with widths from <0.1m to >0.2m and thicknesses from 1mm to 5mm.

Heat loads vary fro <10W to >1 kW

Heat fluxes vary from <1W/cm2 to >100W/cm2

Simple OHP Radiator

Under a series of NASA-funded SBIR efforts, ThermAvant Technologies developed high-efficiency, thin, and lightweight OHP-embedded radiators for medium- and high-heat flux next-generation payloads.

In this spacecraft sidewall (or panel) radiator demonstrator, ThermAvant Technologies and NASA developed an approx. 500mm x 500mm x 1-4mm thick OHP-embedded radiator for environmental testing, including vacuum chamber testing (hence the matte black, high absorptivity coating for IR imaging) and variable gravity testing (0-degrees horizontal, 45-degrees vertical and 90-degree vertical).

Notably, ThermAvant Technologies designed lightweighting features so that the OHP-radiator’s effective density was 1.6 g/cm3. – 40% lighter than solid Al.

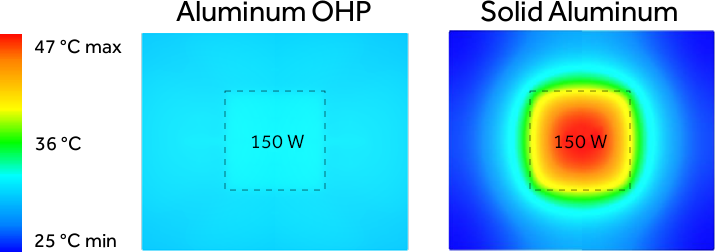

In operation, an electronics chassis attaches to the OHP-embedded radiator’s central boss (uncoated area, approx. 200mmx200mm) which rejects between 100 and 200W, with nominal operation at 150W. However, the OHP-embedded radiator is designed to handle >1000W of heat load, though not required for this demonstrator due to relatively weak radiative rejection boundary.

As a result of its 9x higher conductance and lower density, the OHP radiator enables +14x higher in specific thermal conductance (W/K-g) compared to a solid Aluminum radiator – and can do so in range of gravity fields or transient heat loads.

Simple OHP Radiator vs. Alternatives

| Aluminum OHP | Solid Al | |

|---|---|---|

| Thermal performance | 2 °C per 150 W |

18 °C per 150 W 9x worse than OHP |

| Effective Density |

1.6 g/cm³ Al 6061 T4 w. Selective Coating |

2.7 g/cm³ 1.7x worse than OHP |

| Shape & size |

• Al 6061 T4 sized to approx. 19" × 19" × 0.04–0.16" thick, note variable thickness in photo above (available in multiple coatings, platings or films). • Al OHP typ. has 5% less stiffness and 5% higher modal frequencies than solid Al – utilized thicker cross-sections at interfaces with enclosure and larger spacecraft bus structure. |

|

| Temperature range | -20 °C up to +100 °C | |

| Heritage or maturity-level |

• +1,000 on-orbit (or delivered for launch) OHP spacecraft radiators deployed as of mid-2025 (TRL 9). • Qualified thru MIL-STD vacuum chamber testing, thermal cycling, vibration, shock and pressure cycling for both launch and on-orbit reliability. |

|

350mm x 800mm x 3mm at thinnest center and 12mm at thickest edges

Complex OHP Radiator Example

For this lunar surface rover application, ThermAvant Technologies designed, built, qualified and delivered meter-scale structural radiator panels embedded with the OHP technology to address the mission’s unique thermal-mechanical requirements. These variable-thickness, meter-scale OHP radiators acquire, spread and dissipate waste heat from the rover’s multiple navigation and science payloads.

The customer down-selected ThermAvant Technologies’ OHP-based solution to optimize size, weight, strength, reliability and assembly costs/complexity. The OHP-based panels’ interface not only with the vehicle and its internal payloads but also with one another to array into a larger 1.7m2 radiator with a high-emissivity coating capable of rejecting >1kW under worst-case, transient conditions.

As part of the qualification and flight program, ThermAvant Technologies manufactured and verified thermal-mechanical performance of the OHP-embedded panels which improved thermal conductance by 6.4x compared to mass-equivalent solid Al panels. And, the OHP radiators operated reliably across a range of heat loads, ambient temperatures and gravitational orientations (e.g., ≤1 °C temperature variance when operated in adverse gravity conditions).

Complex OHP Radiator vs. Alternatives

| Aluminum OHP | Solid Al | |

|---|---|---|

| Thermal performance | 1 °C per 20 W (e.g., 6 °C / 125 W) |

1 °C per 3.7 W 5.4x worse than OHP |

| Mass |

3.2 kg Al 6061 T4 w. high-e coatings |

3.9 g 1.2x worse than OHP |

| Shape & Structure |

• Individual panels 800 mm × 350 mm × 3–13 mm (3 mm thinnest OHP section) and designed to array into larger, 1.6 m × 1.1 m radiator with high-e surface coatings • Al OHP typ. has 5% less stiffness and 5% higher modal frequencies than solid Al |

|

| Temperature range | -55 °C up to +70 °C | |

| Heritage or maturity-level |

• <10 OHP lunar rover radiator panels qualified and delivered for launch and >1,000 spacecraft OHPs on-orbit as of mid-2025 • Qualified thru MIL-STD vacuum chamber testing, thermal cycling, vibration, shock and pressure cycling for both launch and lunar surface reliability but not yet deployed on lunar surface as of mid-2025 |

|

Flight-Proven Performance

Albedo and ThermAvant successfully designed and completed the world’s first OHP-based thermal control system for very low earth orbit mid-size satellites, where OHPs conduct heat from multiple payloads through 3D transporters and reject across meter-scale radiators.

The result: a 30% mass reduction and 70% volume savings over legacy thermal systems.

OHP Radiator Tech Specs

Design flexibility and SWaP-C optimization without compromise.

-

Al and Al composites (from 0 to T6 temper) (common for typical satellite radiators)

Cu and Cu composites, including Copper-Molybdenum

Titanium (common for higher temperature applications)

Stainless steel

Ni alloys, including Invar and Kovar

Low-CTE refractory metals, including Molybdenum (Mo) and Tungsten (W)

-

Water

Ketones

Alkanes

Alcohols

Hydrochlorofluorocarbons

Perfluorocarbons

Hydrofluorocarbons

More from cryogenics (below 100 K) to liquid metals (above 1,000 °C)

-

Heat fluxes range from less than 1 W/cm2 to greater than 300 W/cm2

Heat loads per OHP from 1 watt to greater than 10,000 watts

Long-distance OHPs operable at 2 cm length to 2 m length

Gravity independent (e.g., 0.3 m OHPs successfully tested at 9g of adverse gravity and 1.2m OHP successfully tested at 1g adverse gravity)

-

From less than 1 mm in thickness to up to 2 m in length

Customizable widths from less than 2 cm to greater than 1 m

Flat or 3D plate with bosses, through or blind holes, etc.

Platings and dielectric coatings

Chemical conversion coating and anodization

High emissivity black coatings and low absorptivity ceramic coatings

Other features (e.g., integral fin structures, fans, thermoelectrics, etc.)

OHP Radiator FAQs

-

Our embedded OHP radiators combine rugged mechanical support with advanced thermal management by integrating Oscillating Heat Pipes (OHPs) directly into the frame structure. These capillary-driven, passive cooling loops rapidly move heat away from high-flux components—no pumps, fans, or external hardware required. Each frame is engineered to serve as both the mounting surface and the primary thermal pathway, reducing thermal resistance and eliminating the need for bulky cold plates or complex cooling assemblies. Custom-built to integrate with spacecraft and other next higher assemblies, our radiator panels are deployed in mission-critical spaceborne environments to enable the highest payload performance output feasible.

-

Lead times can be as short as 4 weeks for recurring hardware. Custom designs and new builds typically range from 4 to 6 months for first unit delivery, depending on complexity.

-

ThermAvant offers several common form factors to support lab demonstrations and risk reducing efforts but OHPs will typically be designed for the boundary conditions, thermal loading, and heat map of a specific part and application.

-

OHP microchannels can be integrated into thin panels as small as 1 mm in total thickness using aluminum 6061. Since channels are not always necessary across the entire radiator panel to achieve a highly isothermal surface temperature gradient, residual material between channels can be removed for ultra-lightweighting. OHPs have been shown to reduce the effective density of a standard aluminum panel by more than 50%. With the appropriate selection of working fluid, OHPs can operate across a broad temperature range—from cryogenic conditions to liquid metal temperatures—with transport capacity limited only by the available microchannel area.

In contrast, CCHP-mounted radiators require additional mounting hardware and increased panel thickness to accommodate fasteners attached to a solid aluminum radiator substrate. This adds mass to the system and increases the thermal solution’s space claim. CCHPs also have thermal capacity and flux limits, often requiring more heat pipes and mounting components to function effectively at higher temperatures and power levels. Spaceborne CCHPs rely on grooved wick structures to return fluid to the evaporators, but these wicks are limited in performance when operating against gravity. As a result, CCHP ground testing must be carefully oriented to work as intended.

OHPs, by contrast, do not require wicks. They use high-pressure nucleate boiling to passively circulate the working fluid, enabling effective operation in adverse gravity fields. They also eliminate the need for startup heaters and are capable of smooth startup from cold conditions. -

Yes. The OHP is embedded directly into the geometry of the aluminum radiator panel, with no separate components to fail or add bulk. It appears and functions as a solid structural piece but passively moves heat with zero moving parts. Just specify the form factor—ThermAvant builds to match it as a drop in replacement.

-

Pulsating Heat Pipes (PHPs) and Oscillating Heat Pipes (OHPs) refer to the same technology. The terms are used interchangeably in the industry. Regardless of terminology, the focus should be on the efficient heat transfer capabilities and applications of the technology.

-

OHPs can support coatings, primers, and finishes similarly to solid aluminum panels. From highly emissive black coatings to chemical conversion coatings and low-absorptivity ceramic coatings, a wide range of surface treatments can be effectively applied to OHP hardware. ThermAvant’s supply chain and lab facilities are well-equipped to manage surfacing requests.

-

Yes. OHPs can be manufactured with through-holes and threaded or tapped features, allowing for structural mounting to higher-level assemblies and seamless attachment to critical components.

-

Yes. OHPs can be designed and fabricated with complex external geometries and intricate internal channel routing—without compromising the structural integrity of the component.

-

OHP microchannels form structural "I-beam" features within the part’s cross-section. This allows an OHP to retain most of the strength and stiffness of the base material. ThermAvant can provide effective structural properties to support efficient modeling during preliminary design stages at the system level.

-

No. OHP drop-in replacements typically reduce mass compared to solid material equivalents. Microchannels are machined into the raw material, and the voids are partially filled with a low-density working fluid.

-

Cold-start behavior is well-characterized through ThermAvant's proprietary limit models and empirical data. When power is applied, OHPs transition smoothly from low-conductance conditions into high-performance nucleate boiling regimes as temperatures rise.

-

Full-fidelity modeling of OHPs is complex. ThermAvant can support your design by providing either 1) effective thermal conductivity values or 2) vapor-node model inputs to accelerate system-level thermal simulations.

-

ThermAvant has manufactured OHPs ranging from meter-scale dimensions to as small as centimeter-scale. Multi-layer OHPs for structural components can be fabricated, and thicknesses have been demonstrated down to the millimeter scale, depending on material constraints.

-

OHPs have been tested in adverse gravitational orientations without major effects on thermal performance compared to traditional wick based heat pipe/vapor chamber solutions. OHPs operate through nucleate boiling and local, high pressure deltas that have sufficient capability to overcome external body forces.

-

OHPs are manufactured in 4 major steps: 1) initial machining, 2) bonding 3) final machining 4) fluid charging/sealing. Taking aluminum parts as a reference: OHPs will be roughly 3-5x the price of a solid aluminum, precision machined equivalent due to the added manufacturing steps. Items that will drive unit cost are heat map complexity, final part GD&T, part size, material, etc. OHPs provide system level benefits to mass, space claim, thermal performance, and price (reduction in system level complexity) that offset the recurring hardware price. Please engage the ThermAvant business development team for more information.

You Bring the Mission.

We Bring the Solution.

Product Development. Manufacturing. Testing.

From concept to final delivery, ThermAvant partners with your team to design and manufacture OHP-embedded solutions that meet the exact needs of your system.

We support every step:

Collaborative design and modeling based on your layout and power profile

In-house prototyping (in-house brazing and CNC machining capabilities)

On-site lab facilities with high fidelity thermal verification testing

Precision manufacturing for high-volume delivery with robust demand schedules