Built For Space

Mission-proven thermal systems for satellites, spacecraft, and extraplanetary missions.

10,000,000+ OHP hours on orbit.

10,000+ annual output of OHPs created for space-based applications.

15+ years advancing space thermal solutions.

Space-Based OHP Thermal Solutions

To learn more about OHP performance, visit our product pages:

Electronics Enclosures & Heat Frames

OHPs heat frames and OHP enclosures are optimal thermal solutions for accepting a range of heat fluxes from payload devices or circuit cards, and then routing this waste heat through tight, 3-D form factors for easy rejection to the spacecraft's larger thermal control system.

-

OHPs are ideal for imaging/optical payloads, power storage systems (e.g. batteries), on-board "edge-compute processing units, cryocoolers, RF/communication systems.

-

OHPs in circuit board assembly (CCA) heat frames and structural thermal chassis provide effective solutions to hihg powered, densely packed PCBs with passthroughs and mounting features.

-

OHPs embeded in enclosure walls optimally spread heat from VPX CCA heat sink rail contacts over a larger area, in three dimensions, interfacing with thermal transporters or a rejection sink.

Heat Transporters or Thermal Straps

-

OHP thermal transport from key subsystems/payloads to distant/remotely located rejection sinks (e.g. deep space radiators, pumped fluid loops, etc.).

Let us create a custom solution for your space-based platform.

-

OHPs can support multiple heat inputs from onboard payloads or interfaces with rejection sinks.

-

OHPs can be preciscion bent or built with 3D geometry to conform to a platforms space claim. ThermAvant has demonstrated flexible OHPs.

Let us create a custom solution for your space-based platform.

OHPs effectively transport heat long (<0.5 to >1.5 meter) distances allowing payloads and rejection sinks to be remotely located, but still thermally linked.

OHP thermal transporters can be designed be rigid or with compliance/flexibility and routed in 2-D or 3-D form factors.

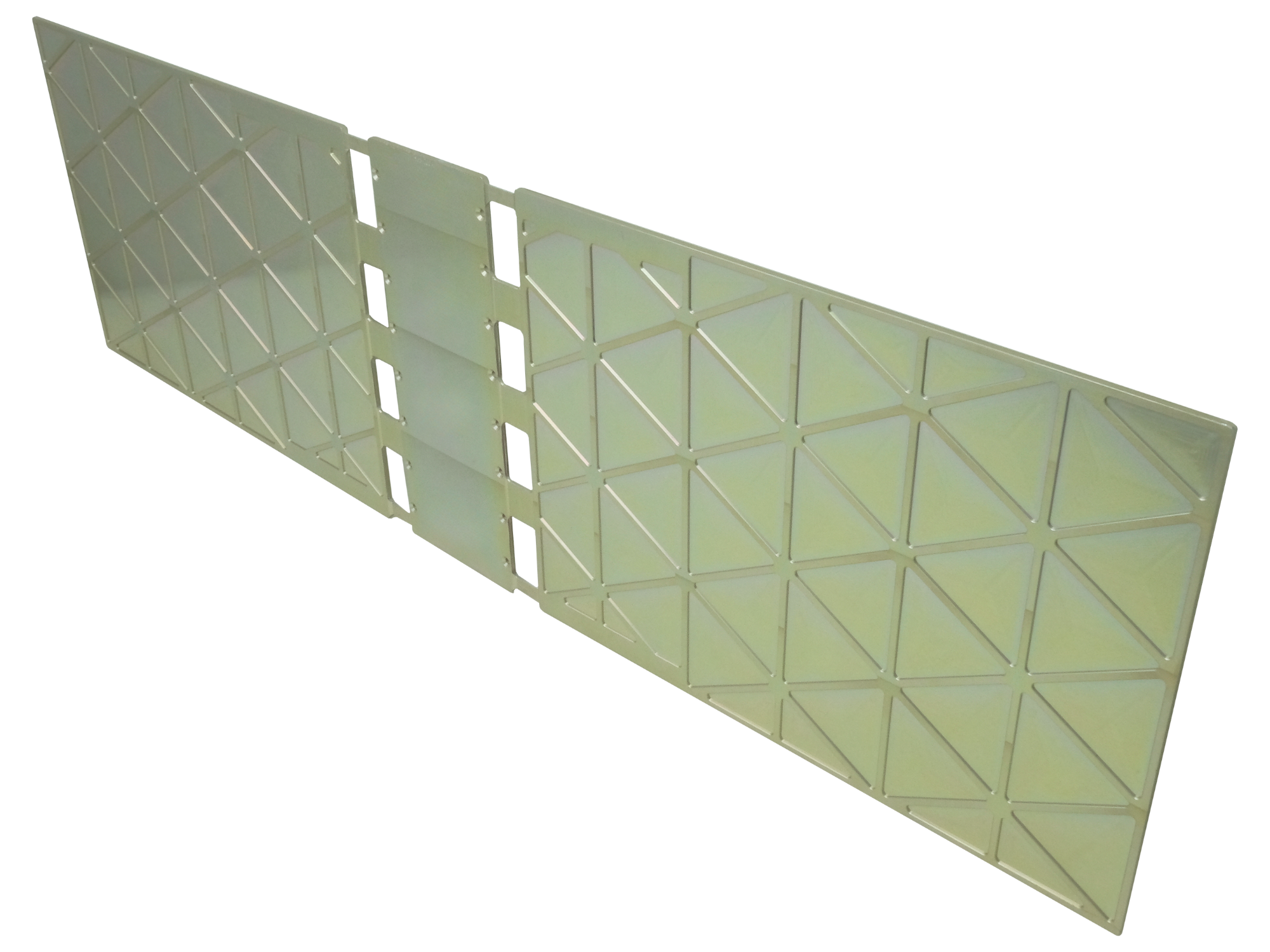

Radiators

-

OHP upport direct mounting of heat generating payloads, thermal transporter interfacing with necessary integrated though mounting features.

-

OHP radiators can be arrayed and deployed for kW/MW rejection with operational redundancy and integrate a monolithically integrated pumped fluid loop heat exchanger.

Let us create a custom solution for your space-based platform. -

OHPs can be ultra lightweighted machining out excess raw material not needed to house the micro channels. OHPs can be bonded with honecomb struture for lightweight rigidity and strength.

Explore our OHP Radiators.

OHPs isothermalize large scale, low areal density, structural panels and radiators for optimal rejection of waste heat to deep space.

OHPs panels can also be designed to operate as solar thermal absorbers, passive or active thermal switches.

Mission-Proven

“MDA Space selects ThermAvant™ Technologies as part of supply chain for MDA AURORA™”

“AFRL, industry launch revolutionary spacecraft technology - Oscillating Heat Pipes”

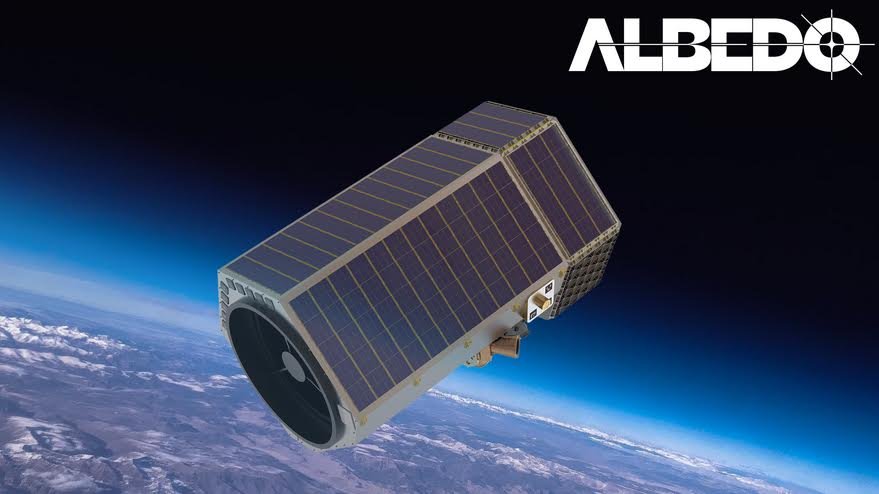

ThermAvant x Albedo Case Study

ThermAvant’s Space Heritage

2007

Founded by Dr. Bill Ma, Dr. Bin Wu, and Joe Boswell.

2009

First National Science Foundation grant awarded.

2015

First aero-defense prototypes delivered and Dr. Ma published OHP textbook.

2017

First launch of OHPs on spacecraft on board OTV5, and represents transition of technology to TRL 9.

2019

Retrieval of OTV5 hardware and successful data comparison to OHP models.

2020

Built first OHPs made 100% in-house (i.e., vertically integrated manufacturing).

2021

1st commercial satellite launch with AFRL and Maxar Technologies.

2021

Large production runs of OHPs (e.g., 1000s of units per order) for mission-critical aerospace and defense customers.

2024

Partnered with MDA Space.

2025

OHPs launched on Albedo’s Clarity-1 Satellite.

2025

Hit 10,000,000 on-orbit hours.

2026+

Contact us to be apart of what’s to come.

Flight-Proven Performance

Albedo and ThermAvant successfully designed and completed the world’s first OHP-based thermal control system for very low earth orbit mid-size satellites, where OHPs conduct heat from multiple payloads through 3D transporters and reject across meter-scale radiators.

The result: a 30% mass reduction and 70% volume savings over legacy thermal systems.

OHP Features & Benefits

-

Overall, OHPs like other fluid-based or heat pipe technologies have heat transfer rates that are 4-400x higher than conventional solid state heat transfer materials. Unlike pumped fluid systems or wick-based heat pipes, OHPs operate passively via unique (and often preferable) pressure-driven fluid flow between heat source(s) and heat sink(s).

For example, our Aluminum heat transporters can move 100s of Watts through <4mm thick cross sections at lengths exceeding 1 meter with thermal conductances of >30 W/K, or effective thermal conductivities of >100,000 W/m-K.

Our OHP radiators can spread 100s or even 1000s of Watts across large surfaces with thermal conductances of >300 W/K.

At the device-level, OHP chip carriers and OHP heat frames can receive heat fluxes from <1 W/cm2 to >300 W/cm2; and these OHPs can spread-and-reject at ultra-high heat transfer coefficients ranging from 5,000 W/m2-K to >50,000 W/m2-K, depending on the size and power of the heat sources and OHPs.

Lastly, OHPs are able to achieve these high performance levels in a range of gravitational orientations (e.g., 0g, -1g and even up to -10g) for reliable operation: on-ground, on-orbit, and during tactical maneuvers.

-

OHPs are integrated into existing components and do not add additional hardware to the platform. Mechanical components become multi-function thermal-mechanical structures. OHP integration negligibly affects the structural performance of the raw material.

OHPs can be made into customized geometries in ultra-thin, conformal form factors — including through features & complex 3D integration. -

OHPs are technology and manufacturing readiness level 9 (TRL/MRL 9) to exacting standards (AS9100) at volume. ThermAvant is producing 1,000s of OHPs per month in drop-in-replacement, conformal form factors.

-

ThermAvant's oscillating heat pipe predictive models have been validated against thousands of empirical data sets. The models include side by side fluid comparison, limits of operation analysis, and predictive performance across wide temperature ranges and power loading conditions. OHPs at ThermAvant are primarily manufactured from aluminum but can be made from ceramics, refractory metals, dielectric materials, and other metallics.

-

More than 10 million hours of successful on orbit mission time. Ground testing can effectively replicate OHP on-orbit/extra planetary performance. OHPs can operate in adverse gravity orientations to enable simpler ground testing. OHPs do not require startup heaters and are proven reliable and strong in high shock and vibration environments. Cold start conditions have been proven to be well handled by OHPs designed for an application.

Proven Thermal Solutions for Mission-Critical Applications

ThermAvant delivers flight-ready thermal hardware. We manage the entire process from concept through manufacturing. If you're developing a satellite, payload, or instrument that needs passive thermal control, let’s talk.

Our innovative thermal systems are trusted by both government and commercial sectors—including 10 of the top 18 U.S. defense contractors.