High-Temperature Oscillating Heat Pipes

Pushing the limits of thermal control for aerospace, nuclear, and advanced energy applications requiring heat transfer at high temperatures (~150-500 °C) and ultra-high temperatures temperature (~500-1800 °C)

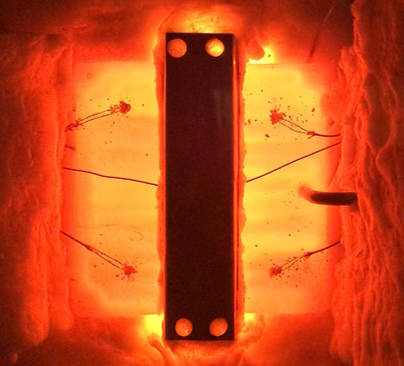

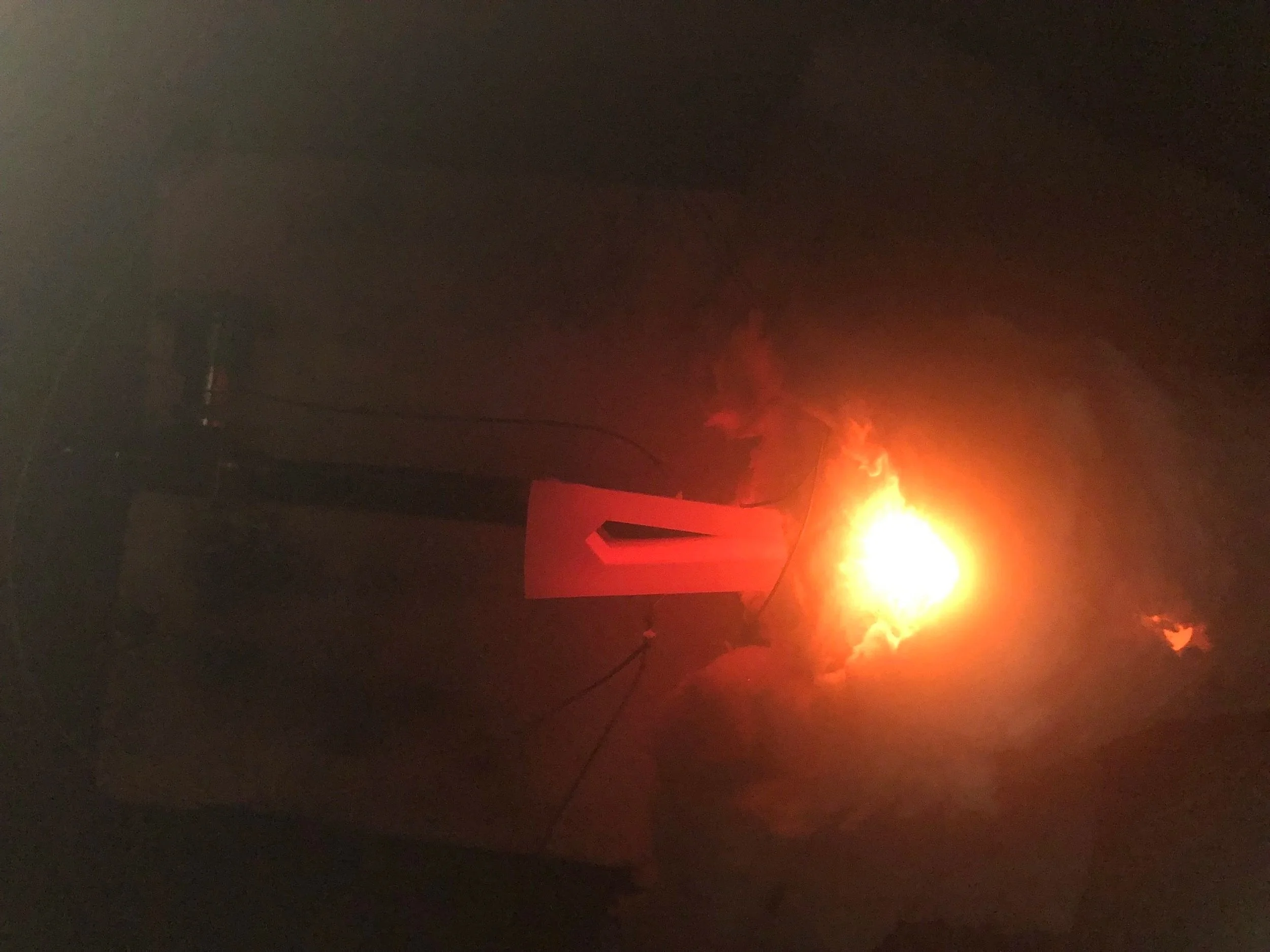

Testing of an Inconel OHP leading edge

Applications

Hypersonic leading edges

Nuclear electric propulsion (NEP)

Radiator panels

Fluid-to-fluid heat exchangers

Heat shields

Aerospace

Reactor cooling

Rejection-side heat rejection

Thermoelectric heat transporters

Nuclear

Waste heat recovery systems

Solar thermal receivers

Fuel cells

Industrial heat exchangers

Semiconductor isothermal liners

Breaking system coolers

Industrial & Energy Systems

Publications

2024 TFAWS: “OHP Radiators for 150-300C Applications”

2024 TFAWS: “Large Format High Temperature Oscillating Heat Pipes”

2025 TFAWS: “High Temperature Oscillating Heat Pipe Radiator” — link coming soon

2022 TFAWS: “An Experimental Investigation of High Temperature Oscillating Heat Pipe for Leading Edge applications”

2024 JANNAF: “OHP Hypersonic Leading Edges” (requires login)

Features, Advantages and Benefits of ThermAvant Tech’s OHPs in High Temperature Applications

Pressure-driven oscillating two-phase fluid flow, as opposed with capillary-driven like conventional wick-based heat pipes

Ultra-high effective thermal conductivities (e.g. 5 to 500x higher than the base material’s)

Producible in tubular, flat plate and complex three-dimensional form factors for a variety of applications (e.g., from 10cm to 3m in length and with cross-sectional heights of 1-10mm)

3D structure OHPs have high strength and relatively low density (e.g., 80% effective density of base material with 95% of base material strength)

Wide range of fluid-material pairs to operate across wide range of medium- and high-temperatures

Images from 2025 NETS:

“Oscillating Heat Pipes for Space Nuclear Power”

ThermAvant Background

2007

Founded by Dr. Bill Ma, Dr. Bin Wu, and Joe Boswell.

2015

First aero-defense prototypes delivered and Dr. Ma published OHP textbook.

2017

First launch of electronics cooling (<100 °C) OHPs on spacecraft on board OTV5, and represents transition of technology to TRL 9.

ThermAvant’s High-Temp Development Timeline

Hypersonics

2019 - 2022

NASA LaRC Phase I-II

2022 - 2025

AFRL/RV Phase III

2023-2025

NASA ARC ACO

2025+

Transitioning into commercial applications

Space Nuclear — Heat Rejection

2020 - 2026

NASA GRC Phase I-III

2024

NASA JPL Phase I

2025+

Transitioning into commercial applications

Space Nuclear — Core Acquisition

2023-2026

NASA GRC Phase I-II

Elevated Temperature OHP Features & Benefits

-

OHPs have exceptional thermal performance, achieving effective thermal properties orders of magnitude greater than the base materials of construction.

The performance of state-of-the art high temperature OHPs is export controlled. Contact ThermAvant for more information

-

OHPs are multifunctional, meeting structural requirements with integrated thermal management. By reducing hot spots, embedding an OHP into a structural component enables more aggressive boundary conditions (e.g. Mach #), without exceeding an established service temperature ceiling.

OHPs can be made into customized geometries in thin, conformal form factors — including through features & complex 3D integration.

-

Elevated temperature OHPs are manufactured from structural materials with known properties at service temperature, e.g. titanium, nickel-based superalloys, and refractory metals.

Working fluids commonly used in conventional heat pipes (water, alkali metals) are suitable in OHPs, in addition to novel alternatives.

Fluid-specific software models for thermal conductance and limits of operation have been validated against empirical datasets, enabling predictive analysis for new designs.

-

Elevated temperature OHPs have been demonstrated with a variety of different architectures, including tubular, flat plate, additively manufactured, and hybrids. Hermetic joints are formed by welding, brazing, and diffusion bonding.

Because OHPs do not require a wick structure, manufacturing is generally less complex than a conventional heat pipe or vapor chamber of similar geometry

ThermAvant has specialized alkali metal heat pipe processing capabilities in-house.

Proven Thermal Solutions for Mission-Critical Applications

We manage the entire process from concept through manufacturing.

World leader in OHP technology with 5 years of experience demonstrating hi-temp solutions (600K to 2,000K)

30+ Engineers dedicated to continuous OHP technology and OHP manufacturing improvements

Unique Alkali metal OHP processing capabilities in-house

Successfully applied Hi-Temp OHPs (see publications, above)

Actively engaged with NASA, DoD, and Primes to apply Hi-Temp OHPs to hypersonic