CASE STUDY

Comparing 1 mm Oscillating and Flattened Heat Pipe Thermal Performance

Oscillating Heat Pipes (OHPs) achieve superior heat transfer and stiffness at half the density, setting a new standard for thin, high-performance electronics cooling.

Study Summary

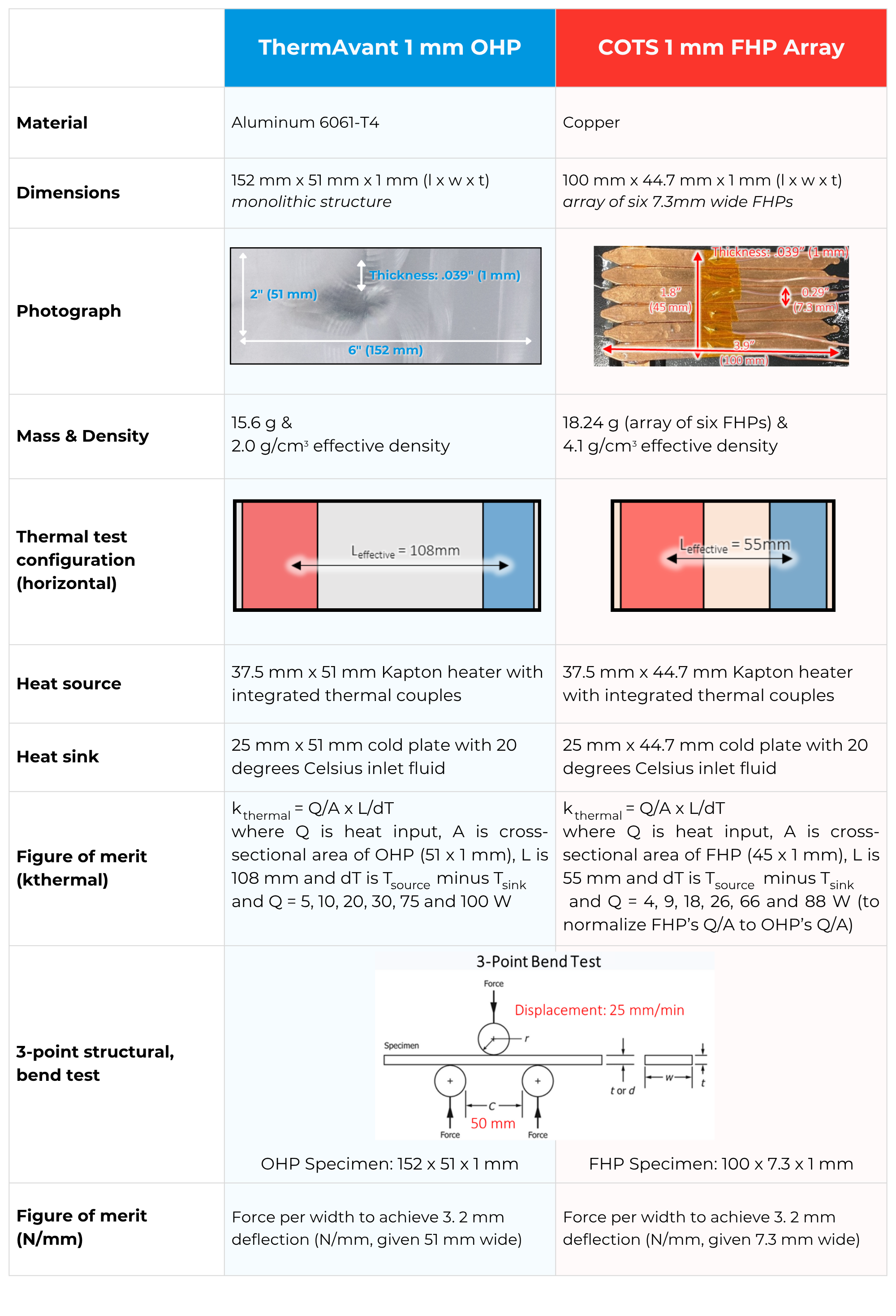

ThermAvant Tech conducted thermal and structural testing of a 1 mm thick Aluminum Oscillating Heat Pipe (OHP) and of an array of 1 mm-thick Copper Flattened Heat Pipes (FHP).

Compared to the FHPs, the OHP demonstrated:

1.7× higher thermal conductivity at 8–10 W of heat transfer

18× higher thermal conductivity at 80–100 W

3.6× greater structural stiffness and 51% less massive (lower density) than the flattened heat pipes

Closeup of 1 mm thick OHP with U.S. Quarter (24 mm diameter x 1.8 mm thick)

Problem & Opportunity

Rising demand for smaller, more powerful electronic systems faces a critical heat transfer bottleneck, not only with regards to higher heat fluxes (e.g., W/cm²) but also in volumetric terms (e.g., W/cm³). Increasingly compact enclosures can no longer rely on conventional thermal-mechanical packaging to acquire, transfer relatively high heat loads across sub-millimeter cross-sections without unacceptably high temperature rises.

This industry-wide packaging challenge necessitates transformative heat transfer devices with profiles ≤1 mm thick which can transfer 10s to 100s of W without compromising device temperatures, or structural integrity.

Common applications for ultra-thin OHPs include: personal devices (phones, watches, tablets), laptops, high-frequency power electronics, densely arrayed Li-ion cells, and more.

Study Results

To measure the performance of a 1mm thick Oscillating Heat Pipe (OHP) versus an array of 1mm thick commercial-off-the-shelf (COTS) flattened heat pipes (FHPs), ThermAvant Tech conducted an empirical test of both their thermal and structural properties, as summarized below.

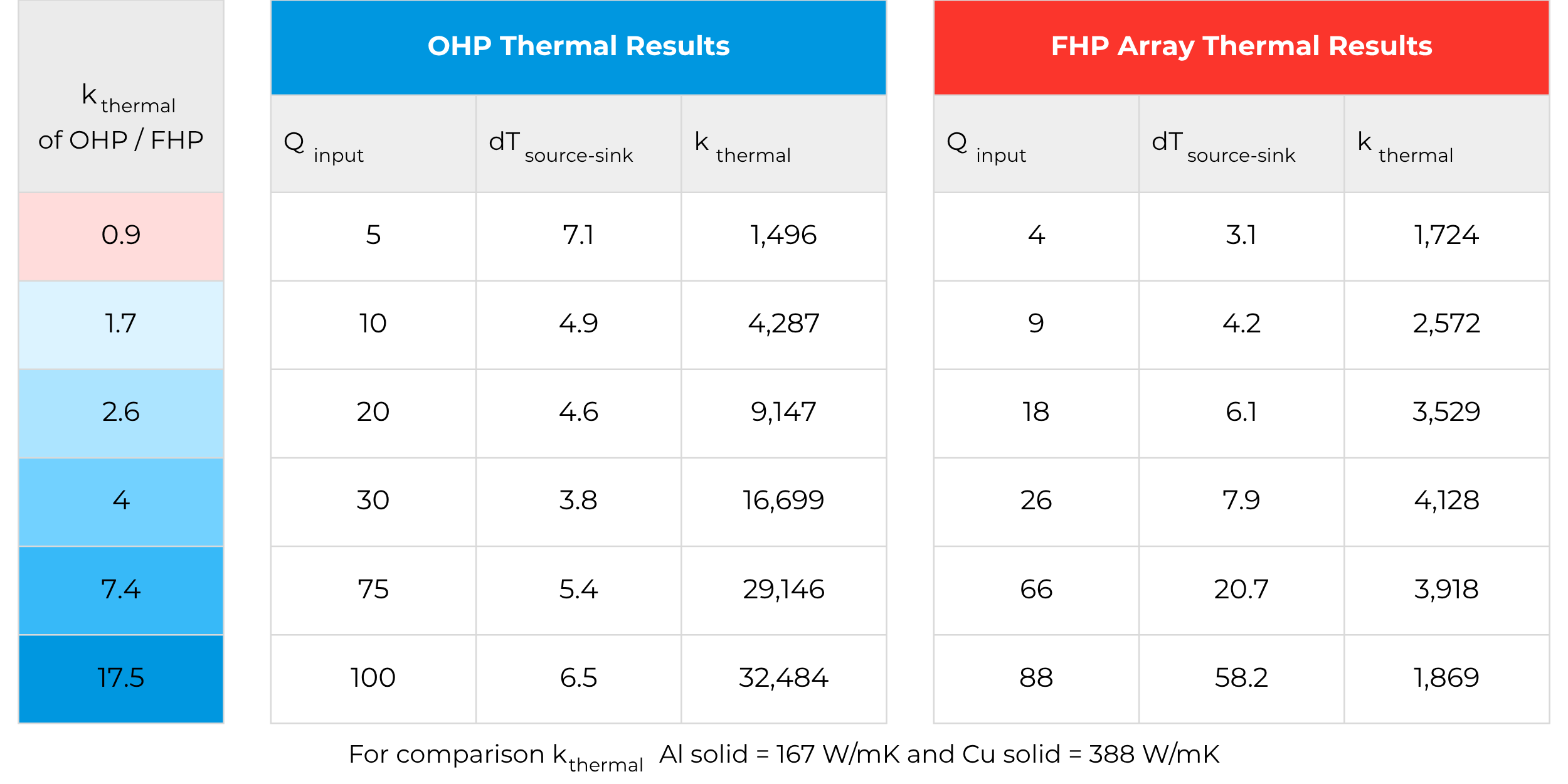

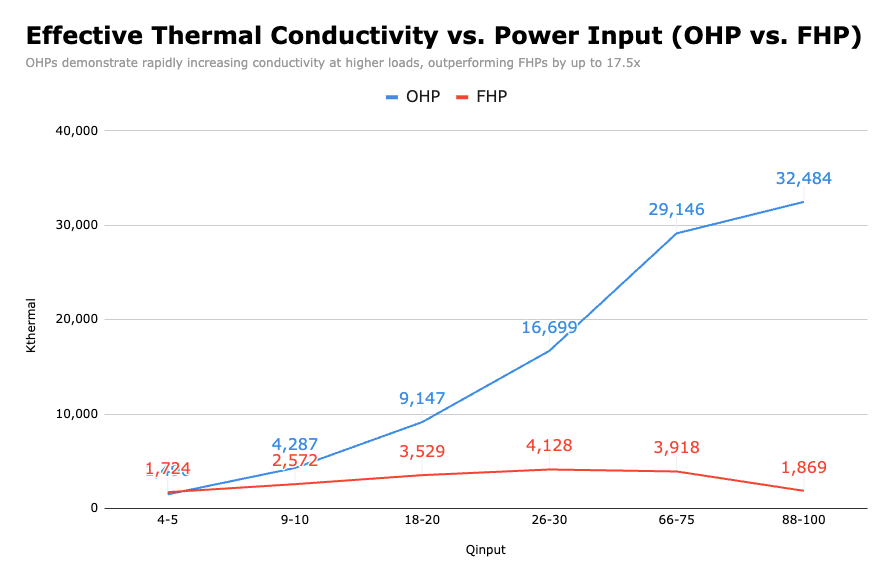

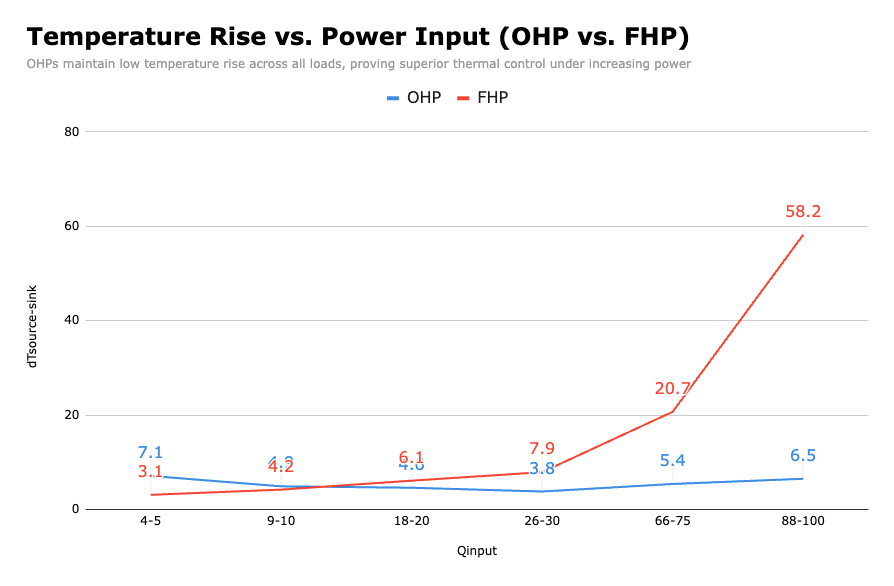

Compared to the 1mm FHP, the 1mm OHP demonstrated a 17.5x higher kthermal at maximum power of 100 W, or 88 W equivalent for the 44.7 mm wide FHP. And, the OHP demonstrated 1.7 - 7.4x higher kthermal at 10-75 W loads. At the lowest power (e.g., 5 W OHP), the FHP demonstrated better performance.

Thermal Results: OHPs Outperform FHPs, e.g. 17x at 100W

As shown in table above, test results are in-line with theoretical modeling of OHPs vs. wick-based FHPs. I.e., at low fluxes the copper water FHPs demonstrate superior performance while OHPs require more power to “start up”. However, even at 10 W equivalent heat loads, OHPs have higher capabilities, and overall performance once rigorous flow occurs. On the contrary, FHPs see declining performance as heat loads approach critical limits, e.g., see declining kthermal of FHP’s last two power steps above.

Structural Performance: OHP has 3.6x greater stiffness with 51% less mass

The OHP proved to be substantially more rigid, a vital consideration for applications where the heat spreader is an integral structural component.

The OHP deflected to the critical 3.2 mm at 4.8 N/mm whereas the FHP deflected by the same magnitude at 1.3 N/mm.

Notably, a solid Al 6061 T6 temper control unit (51 x 152 x 1 mm) deflected 3.2mm at 5.9 N/mm; i.e, the OHP’s stiffness was 81% of the solid equivalent. To summarize, OHP is 3.6 times stiffer than the FHP, and OHP is 51% lower density than the FHP.

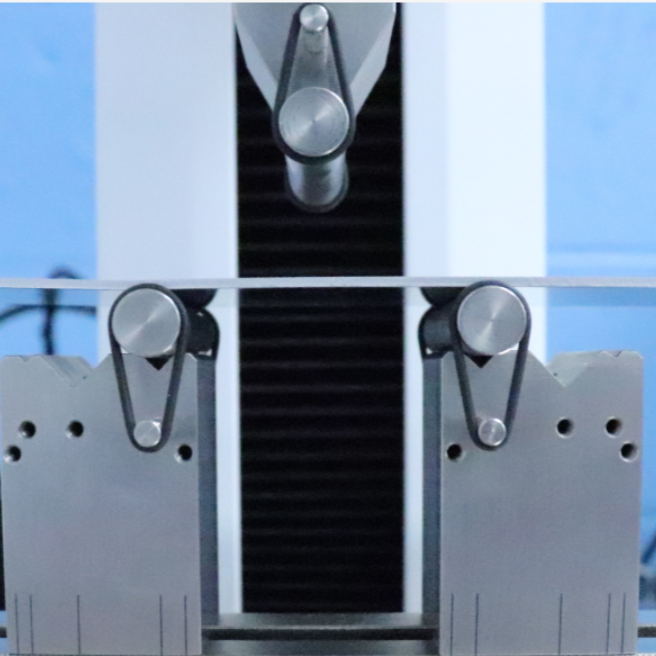

3-point structural bend test with Al 1 mm thick x 51 mm wide test specimen

These findings validate the 1 mm OHP as a superior thermal solution for compact, high-power electronics packages: outperforming FHPs in heat transport capacity, thermal conductivity, and rigidity - while requiring 51% less mass. Ultra-thin OHPs are the enabling technology for next-generation high-power electronics.

To learn more about 1mm thick OHPs for your terrestrial electronics packaging application or spacecraft thermal control solutions (e.g. 1mm thermal straps or 1mm thick radiators), please contact us.